You’ve noticed strange discoloration on your pool surfaces – blue-green stains around return jets, brown streaks near ladders, or mysterious dark spots that won’t brush away. These are metal stains, and they’re more common in Tennessee pools than many owners realize. The good news is that metal stains can be completely removed with the right approach. The bad news is that if you don’t do it correctly, the stains will return within weeks.

After treating numerous Tennessee pools for metal staining issues, I’ve learned that success requires identifying the metal source, following the proper treatment sequence, and using products specifically designed for complete metal removal. This comprehensive guide will walk you through the entire process, from diagnosis to final treatment, ensuring your pool surfaces return to their original beauty permanently.

🔬 Metal Staining Truth: “Removing stains from surfaces is easy. Removing metals from water so stains never return requires systematic treatment and the right products.”

Understanding Metal Staining in Tennessee Pools

Why Tennessee Pools Are Prone to Metal Staining

Copper staining dominance in our region: Unlike northern states where iron staining is more common, Tennessee pools primarily suffer from copper staining due to our unique combination of factors:

Equipment-related copper sources:

- Pool heaters with copper heat exchangers – Common in Tennessee’s extended season pools

- Copper plumbing components in older pool systems

- Corroded pump and filter connections with copper fittings

- Heat pump systems with extensive copper coil systems

Structural copper sources:

- Pool ladders and handrails with copper alloy components

- Light fixtures and electrical connections containing copper

- Screws and hardware made from copper alloys that corrode over time

- Automatic pool cleaners with copper electrical components

The Tennessee Climate Factor

Why our climate accelerates metal corrosion:

- Extended pool season means equipment runs longer, stressing components

- High summer temperatures accelerate chemical reactions and corrosion

- Humidity and temperature swings stress equipment seals and connections

- Frequent storms can cause pH swings that promote corrosion

Water chemistry challenges:

- pH instability from temperature changes promotes metal dissolution

- High evaporation rates concentrate corrosive chemicals

- Extended heating season stresses heat exchanger components more than northern climates

Identifying Metal Types and Sources

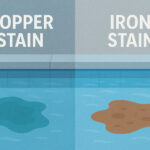

Copper Staining Characteristics

Visual identification:

- Blue-green stains on pool surfaces, especially near returns

- Turquoise or teal discoloration in water after shocking

- Dark blue-black stains in severe cases

- Concentrated staining around equipment returns and fittings

Common copper sources in Tennessee pools:

- Pool heaters – Heat exchanger corrosion from pH imbalance

- Pump and filter housings – Copper fittings and connections

- Pool ladders and rails – Bronze or brass components corroding

- Electrical components – Light fixtures, bonding wires, junction boxes

- Plumbing fittings – Older copper pipe connections and valves

Iron Staining Characteristics

Visual identification:

- Brown or rust-colored stains on pool surfaces

- Yellow-brown water discoloration after shocking

- Orange or reddish deposits along waterline

- Rust stains on concrete and tile surfaces

Iron sources (less common in Tennessee):

- Well water with high iron content

- Rusted steel components in older pools

- Iron-based algaecides overuse or reaction

- Corroded rebar in concrete pools

🎯 Tennessee Reality: “In my experience, 80% of metal staining in Tennessee pools comes from copper corrosion caused by poor pH control attacking expensive equipment.”

The Critical Importance of Source Identification

Why Finding the Source Comes First

The expensive mistake most pool owners make: Treating stains without eliminating the source means the stains will return within weeks or months. You’ll spend hundreds on treatment products only to watch new stains appear as more metals enter the water.

Source identification process:

- Visual equipment inspection – Look for blue-green discoloration on copper components

- pH history analysis – Extended low pH periods cause rapid copper dissolution

- Stain location mapping – Stains concentrate near metal sources

- Professional equipment assessment – Internal component inspection by qualified technician

Common Tennessee Pool Metal Sources

Pool Heater Heat Exchangers

Why heaters are the #1 copper source:

- Copper tubes in heat exchanger dissolve when pH drops below 7.0

- Extended heating season in Tennessee increases exposure time

- Temperature cycling stresses connections and seals

- Poor water balance accelerates corrosion dramatically

Diagnostic signs:

- Blue-green stains concentrated around heater returns

- Recent pH control problems in pool maintenance history

- Visible corrosion on heater connections and fittings

- Reduced heating efficiency as heat exchanger corrodes

Solution requirements:

- Bypass heater during metal treatment process

- Professional heater inspection to assess internal damage

- Heat exchanger replacement if severely corroded

- Improved pH control to prevent future corrosion

Pool Ladders and Handrails

Common corrosion points:

- Stainless steel with copper alloy components corrode in pool water

- Mounting screws and hardware often contain copper or brass

- Electrical bonding connections use copper wire and fittings

- Anchor sockets may have copper components

Inspection process:

- Visual examination of all metal components for discoloration

- Electrical continuity testing of bonding systems

- Hardware removal and inspection for corrosion

- Professional electrical assessment if bonding system affected

Plumbing and Equipment Connections

Copper corrosion sources:

- Pump housing connections with copper or brass fittings

- Filter system plumbing using copper transition fittings

- Heater plumbing connections with copper components

- Valve bodies and actuators containing copper alloys

Optimal Treatment Timing and Conditions

Why Late Season or Early Season Treatment Works Best

Temperature considerations:

- Ideal water temperature: 65°F or cooler

- Why cooler water matters: Reduced algae activity during chlorine-free treatment period

- Tennessee timing: Late October/November or early March/April

- Risk management: Lower temperatures reduce algae bloom risk

Seasonal advantages:

- Reduced pool usage during treatment period

- Less chemical demand from cooler water and lower bather load

- Equipment accessibility for source repair during off-peak season

- Professional availability for equipment work during slower season

The Two-Week Treatment Timeline

Why metal removal takes time:

- Chemical processes require time to work completely

- Filter circulation needs time to remove all suspended metals

- Sequential treatments must be properly spaced

- Verification testing ensures complete removal

Treatment phases:

- Days 1-3: Source elimination and initial stain treatment

- Days 4-10: Metal removal and water circulation

- Days 11-14: Final filtration and verification testing

- Post-treatment: Water rebalancing and system restart

⏰ Timing Truth: “Rushing metal treatment guarantees failure. The metals will return, and you’ll repeat the expensive process within months.”

The Proper Metal Staining Treatment Sequence

Phase 1: Source Elimination (Days 1-3)

Critical first step – Stop the source:

For heater-related copper:

- Bypass heater completely during treatment

- Professional heater assessment for internal damage

- Heat exchanger replacement if corroded (before treatment)

- Improved pH control system installation if needed

For ladder/hardware copper:

- Remove corroded components completely

- Replace with appropriate materials (proper stainless steel grades)

- Inspect and replace mounting hardware

- Verify electrical bonding integrity after replacement

For plumbing-related copper:

- Isolate corroded fittings during treatment

- Replace copper components with appropriate alternatives

- Upgrade to better materials to prevent future corrosion

- Professional plumbing assessment for hidden issues

Phase 2: Surface Stain Removal (Days 1-2)

For Copper Stains – Ascorbic Acid Treatment

Ascorbic acid (Vitamin C) application:

- Product: Pure ascorbic acid or vitamin C tablets

- Application method: Direct application to stained areas

- Dosage: 1 pound per 10,000 gallons as starting point

- Results: Stains disappear within minutes to hours

Application technique:

- Lower water level if treating waterline stains

- Apply directly to stained surfaces

- Brush gently to distribute acid over stained area

- Allow contact time – 15-30 minutes for most stains

- Brush again and observe stain removal

For Iron Stains – BioGuard Iron Stain Remover

Product specifications:

- BioGuard Iron Stain Remover specifically formulated for iron

- Application method: Follow manufacturer’s dosing instructions

- Contact time: Several hours to overnight for complete removal

- Effectiveness: Removes rust and iron stains from all surfaces

Phase 3: Water Metal Removal (Days 3-10)

BioGuard Pool Magnet Plus Treatment

Why Pool Magnet Plus is essential:

- Chelation process: Binds to dissolved metals in water

- Prevents redeposition: Keeps metals suspended for filter removal

- Complete removal: Ensures metals don’t return to cause new stains

- Proven effectiveness: Specifically formulated for pool metal removal

Application process:

- Calculate exact dosage based on pool gallonage

- Distribute evenly around pool perimeter

- Maintain circulation 24 hours per day during treatment

- No chlorine addition during active treatment period

- Monitor pH levels and maintain 7.2-7.6 range

Critical treatment requirements:

- Zero chlorine levels during active treatment (chlorine interferes with process)

- Continuous circulation to keep metals suspended

- pH maintenance at 7.2-7.6 for optimal chelation

- Filter cleaning every 2-3 days during treatment

Phase 4: Final Metal Removal (Days 10-14)

BioGuard Sparkle Up Filter Treatment

Why Sparkle Up is the final critical step:

- Removes metals from filter media that could reintroduce stains

- Enhances filtration of remaining suspended metals

- Filter sizing specific – dosage based on filter type and size

- Completes removal process for permanent stain prevention

Application based on filter type:

Sand filters:

- Dosage: Follow manufacturer’s instructions for filter size

- Application method: Add directly to skimmer during circulation

- Timing: Days 10-12 of treatment process

- Backwash schedule: Increase frequency during treatment

Cartridge filters:

- Filter replacement: Install new cartridges before Sparkle Up application

- Dosage adjustment: Follow cartridge filter-specific instructions

- Cleaning schedule: Replace cartridges every 2-3 days during treatment

- Final replacement: New cartridges after treatment completion

DE filters:

- Fresh DE addition: New diatomaceous earth before treatment

- Dosage calculation: Based on filter grid square footage

- Backwash protocol: More frequent backwashing during treatment

- Final cleaning: Complete grid cleaning after treatment

Post-Treatment Verification and System Restart

Confirming Complete Metal Removal

Testing requirements:

- Professional water analysis for dissolved metals

- Copper levels: Should be undetectable (under 0.1 ppm)

- Iron levels: Should be undetectable (under 0.1 ppm)

- Visual inspection: No new stains after 48 hours of normal operation

What to test:

- Total dissolved metals with professional analysis

- Copper and iron specifically if available

- Water clarity and overall quality

- pH stability after chemical rebalancing

System Restart Procedure

Gradual reactivation:

- Reestablish chlorine residual slowly (0.5 ppm initially)

- Monitor for any stain reappearance over 48-72 hours

- Gradually increase chlorine to normal operating levels

- Reactivate all equipment including heaters and automation

- Resume normal maintenance routine

Post-treatment maintenance:

- Enhanced pH monitoring for 30 days after treatment

- Weekly professional testing for first month

- Equipment inspection for any new metal corrosion

- Preventive maintenance schedule establishment

Preventing Future Metal Staining

Water Chemistry Management

Critical pH control:

- Maintain pH 7.2-7.6 consistently to prevent metal corrosion

- Test pH 2-3 times weekly during swimming season

- Immediate correction of pH imbalances

- pH controller installation for automatic maintenance

Regular monitoring schedule:

- Weekly testing of all chemical parameters

- Monthly professional analysis including metals testing

- Equipment inspection for early corrosion signs

- Maintenance log tracking all chemical additions and readings

Equipment Protection Strategies

Heater protection:

- Bypass during aggressive chemical treatments (shocking, pH adjustment)

- Regular professional inspection of heat exchanger condition

- pH monitoring before and after heating cycles

- Heat exchanger replacement at first signs of corrosion

Metal component upgrades:

- Marine-grade stainless steel for replacement hardware

- Non-metallic alternatives where appropriate

- Proper electrical bonding to prevent galvanic corrosion

- Regular hardware inspection and replacement program

Early Detection Systems

Visual inspection routine:

- Monthly equipment inspection for corrosion signs

- Water quality monitoring for color changes after shocking

- Stain appearance tracking to identify new sources quickly

- Equipment performance monitoring for efficiency changes

Professional monitoring:

- Quarterly equipment inspection by qualified technician

- Annual heat exchanger assessment if heater present

- Electrical system inspection for bonding and grounding integrity

- Preventive maintenance scheduling for critical components

Why BioGuard Products Are Essential for Success

The Science Behind Effective Metal Removal

BioGuard’s systematic approach:

- Product compatibility – All products work together synergistically

- Proven formulations – Years of testing and refinement

- Complete removal – Not just stain hiding but metal elimination

- Professional support – Technical assistance when needed

Why generic products fail:

- Incomplete metal removal leads to stain return

- Product interactions can create new problems

- Insufficient chelation leaves metals in water

- No technical support when problems arise

Specific Product Benefits

BioGuard Iron Stain Remover:

- Iron-specific formulation for complete iron stain removal

- Safe for all pool surfaces including vinyl, fiberglass, and plaster

- Proven effectiveness in Tennessee water conditions

- Professional-grade concentration for complete treatment

BioGuard Pool Magnet Plus:

- Advanced chelation chemistry for complete metal removal

- Prevents stain return by removing metals from water

- Filter-friendly formulation enhances filtration efficiency

- Time-tested reliability in professional applications

BioGuard Sparkle Up:

- Filter-specific treatments for different filter types

- Removes trapped metals that other products miss

- Enhances filtration of remaining contaminants

- Completes treatment process for permanent results

Common Treatment Mistakes That Cause Failure

Skipping Source Identification

The expensive error: Treating stains without finding and eliminating the metal source guarantees stain return within weeks or months.

Why it happens:

- Impatience to see immediate stain removal results

- Cost avoidance of equipment repairs or replacement

- Misunderstanding of the treatment process

- DIY mentality without proper diagnosis

Real consequences:

- Stains return within 2-8 weeks of treatment

- Repeated treatment costs that exceed source repair costs

- Progressive equipment damage from continued corrosion

- Pool surface damage from repeated stain cycles

Using Chlorine During Treatment

Why chlorine destroys treatment:

- Interferes with chelation process that removes metals

- Oxidizes treatment chemicals before they can work

- Creates chloramines from organic treatment products

- Prevents complete metal removal from water

How this happens:

- Automatic chlorinators not properly shut off

- Salt systems continuing to generate chlorine

- Shocking during treatment thinking it will help

- Impatience with algae concerns leading to premature chlorine addition

Inadequate Treatment Time

Why rushing fails:

- Chemical processes require time to work completely

- Filter circulation needs time to remove all metals

- Incomplete removal leads to rapid stain return

- Verification testing skipped in rush to finish

Proper timeline respect:

- Full 14-day process regardless of visual improvement

- Continuous circulation throughout treatment period

- Professional testing before declaring treatment complete

- Patient approach for permanent results

Wrong Water Temperature

Why hot water treatment fails:

- Algae blooms develop during chlorine-free period

- Chemical instability from high temperatures

- Accelerated metal redeposition in hot water

- Treatment chemical breakdown from heat

Temperature management:

- Wait for cooler weather rather than rushing treatment

- Monitor algae development carefully during treatment

- Shade pool if possible during treatment period

- Professional guidance for temperature management

Professional Support and When to Seek Help

When DIY Treatment May Not Be Sufficient

Complex situations requiring professional help:

- Multiple metal types present simultaneously

- Severe equipment corrosion requiring replacement

- Repeated treatment failures from previous attempts

- Electrical or plumbing modifications needed

Equipment-related complications:

- Heater internal damage assessment and repair

- Electrical bonding problems affecting metal corrosion

- Plumbing modifications to eliminate metal sources

- Pool surface damage from long-term staining

Working with Pool Professionals

What to expect from quality service:

- Complete source identification before treatment begins

- Equipment assessment and repair recommendations

- Professional-grade treatment products and procedures

- Follow-up testing to verify complete metal removal

- Prevention planning to avoid future problems

Questions to ask potential service providers:

- How do you identify metal sources before treatment?

- What products do you use for complete metal removal?

- How do you verify treatment success?

- What prevention recommendations do you provide?

- Do you guarantee your metal stain removal work?

Long-Term Pool Surface Protection

Understanding Stain Prevention vs Removal

Prevention is always cheaper:

- Consistent water balance prevents metal dissolution

- Regular equipment maintenance prevents corrosion

- Early detection allows minor corrections

- Professional monitoring catches problems early

Removal costs vs prevention costs:

- Metal stain treatment: Hundreds in chemicals plus 2 weeks downtime

- Prevention maintenance: Monthly chemical costs and annual inspections

- Equipment replacement: Thousands if corrosion not prevented

- Surface refinishing: Tens of thousands if staining becomes permanent

Building a Stain Prevention Program

Monthly prevention checklist:

- pH testing and adjustment to prevent metal corrosion

- Equipment inspection for early corrosion signs

- Water quality monitoring for metal contamination

- Professional testing for comprehensive analysis

Annual prevention program:

- Equipment professional inspection and maintenance

- Metal testing as part of complete water analysis

- Hardware replacement program for aging components

- System upgrades to improve chemistry control

Conclusion

Metal staining in Tennessee pools is primarily a copper corrosion problem caused by equipment damage from poor water chemistry control. While the stains are unsightly, the real issue is the ongoing metal source that will continue causing problems until properly addressed.

Successful metal stain removal requires identifying and eliminating the source first, followed by systematic treatment with products specifically designed for complete metal removal. BioGuard’s Iron Stain Remover, Pool Magnet Plus, and Sparkle Up provide the proven chemistry needed for permanent stain elimination when used in the proper sequence.

The treatment process takes time and patience – typically two weeks with specific temperature and chemical requirements. Attempting to rush the process or skip steps virtually guarantees treatment failure and stain return.

Most importantly, prevention through proper pH control and equipment maintenance costs far less than repeated stain removal treatments and equipment replacement. Once you’ve eliminated existing stains, maintaining proper water balance prevents new metal dissolution and protects your investment long-term.

💎 Metal Staining Success: “Source identification + proper products + adequate time + post-treatment prevention = permanent stain removal and surface protection.”

With proper understanding and the right approach, metal stains can be completely eliminated from Tennessee pools, restoring beautiful surfaces and preventing future problems through improved maintenance practices.

Dealing with metal staining in your Tennessee pool? Share photos of your stains and details about your pool equipment in the comments below. With information about your specific situation and equipment, we can help you identify the likely metal source and develop an effective treatment plan using the proper BioGuard products.