Every Tennessee pool owner faces problems – it’s not a matter of if, but when. From sudden green water to equipment failures to mysterious chemical imbalances, pool problems always seem to happen at the worst possible time. After years of helping Tennessee pool owners diagnose and fix every imaginable pool issue, I’ve compiled this comprehensive troubleshooting guide to help you identify problems quickly and fix them correctly the first time.

This guide covers the most common pool problems I see in Tennessee, their underlying causes, and step-by-step solutions that actually work in our challenging climate. More importantly, I’ll help you understand why these problems happen so you can prevent them from recurring.

🔧 Troubleshooting Truth: “Most pool problems aren’t random bad luck – they’re predictable consequences of specific causes that can be identified and fixed.”

How to Use This Troubleshooting Guide

The Systematic Approach

Before you start throwing chemicals at problems:

- Identify symptoms accurately – What exactly is wrong?

- Determine timing – When did you first notice the problem?

- Consider recent changes – Weather, usage, chemical additions, equipment changes

- Test water chemistry – Many problems have chemical imbalances as root causes

- Check equipment operation – Pumps, filters, heaters, cleaners

Tennessee-Specific Considerations

Our climate creates unique challenges that affect both problem causes and solutions:

- Rapid temperature changes stress equipment and chemistry

- High humidity affects evaporation and chemical balance

- Intense UV exposure breaks down chemicals faster

- Heavy summer storms dilute chemistry and add contaminants

- Extended season means more opportunities for problems

🎯 Diagnostic Tip: “The key to successful troubleshooting is finding the root cause, not just treating symptoms. Fix the cause and the symptom disappears permanently.”

Water Quality Problems

Cloudy Water – The Most Common Complaint

Symptoms:

- Water appears milky, hazy, or unclear

- Cannot see bottom of pool clearly

- Water may have slight color tint

Type 1: Chemical Cloudiness

Causes:

- Improper pH levels (too high or too low)

- High total alkalinity

- Calcium hardness imbalance

- Inadequate sanitizer levels

Tennessee factors:

- Heat accelerates chemical reactions

- Evaporation concentrates chemicals unpredictably

- Rain dilutes chemistry rapidly

Diagnostic tests:

- pH reading outside 7.2-7.6 range

- Alkalinity above 150 ppm or below 80 ppm

- Chlorine reading below 1.0 ppm

Solution steps:

- Test and balance pH first – Adjust to 7.2-7.4 range

- Adjust alkalinity if needed – Target 100-120 ppm

- Shock pool with granular chlorine

- Run filter continuously until water clears

- Add clarifier if cloudiness persists after 24 hours

Type 2: Filtration Cloudiness

Causes:

- Dirty or clogged filter media

- Inadequate pump runtime

- Poor water circulation

- Undersized filtration system

Tennessee factors:

- Heavy pollen loads in spring

- Frequent storms add debris

- Extended season overworks filtration

Diagnostic signs:

- Poor water movement at returns

- High pressure on filter gauge

- Short time between filter cleanings

Solution steps:

- Clean or backwash filter immediately

- Increase pump runtime to 12+ hours daily

- Check for circulation dead spots

- Inspect and clean skimmer baskets

- Consider filter upgrade if problems persist

Type 3: Organic Cloudiness

Causes:

- High bather load

- Organic debris decomposition

- Insufficient oxidation

- Poor sanitation

Tennessee factors:

- Hot weather increases organic contamination

- Humidity slows natural breakdown

- Extended swimming season increases bather load

Diagnostic signs:

- Chlorine disappears quickly

- Strong chlorine smell (chloramines)

- Cloudiness appears after heavy pool use

Solution steps:

- Shock heavily with granular chlorine

- Brush all surfaces to break up organic matter

- Run filter continuously

- Add enzyme product to break down oils and organics

- Increase regular sanitizer levels

Green Water – Algae Invasion

For detailed algae treatment, see our Green Pool Emergency guide. Here’s the quick diagnostic:

Light Green Algae

Symptoms:

- Slight green tint to water

- Can still see pool bottom

- Walls may feel slightly slippery

Immediate action:

- Shock with double normal dose

- Add copper-based algaecide

- Brush all surfaces vigorously

- Run filter 24 hours continuously

Dark Green Algae

Symptoms:

- Cannot see pool bottom

- Water appears swamp-like

- Strong algae smell

Immediate action:

- Shock with triple normal dose

- Add copper-based algaecide

- Brush extensively twice daily

- Prepare for 5-7 day recovery process

Black or Dark Spots – Black Algae

Symptoms:

- Dark spots on pool walls or floor

- Spots feel rough or raised

- Regular brushing doesn’t remove spots

- Spots return quickly after treatment

Why black algae is serious:

- Has protective coating and root system

- Extremely chlorine-resistant

- Can permanently stain pool surfaces

- Requires aggressive treatment

Treatment protocol:

- Brush spots with steel brush to break protective coating

- Apply granular shock directly to brushed areas

- Use black algae-specific algaecide

- Maintain high chlorine levels (5-10 ppm) for weeks

- Brush daily until completely eliminated

Tennessee challenge: Our humidity and heat create ideal black algae conditions. Prevention is much easier than cure.

Brown or Yellow Water

Possible causes:

- Metal contamination (iron, copper, manganese)

- Organic staining from leaves or debris

- Chemical reaction with metal equipment

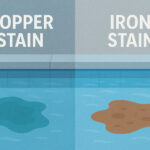

Metal Staining

Symptoms:

- Water turns brown, yellow, or green immediately after shocking

- Stains appear on pool surfaces

- Metal taste in water

Sources in Tennessee:

- Well water with high iron content

- Corroded equipment releasing metals

- Metal-based algaecides overuse

Solution:

- Stop adding shock immediately

- Add metal sequestrant according to package directions

- Lower pH to 7.0-7.2 to help metal suspension

- Run filter continuously

- Consider ascorbic acid treatment for severe staining

Organic Staining

Symptoms:

- Brown or yellow color develops gradually

- Often worse in morning after overnight circulation

- May have organic smell

Tennessee causes:

- Decomposing leaves and organic debris

- Tannins from tree coverage

- Inadequate oxidation of organic matter

Solution:

- Remove all visible organic debris

- Shock heavily to oxidize organic matter

- Add enzyme product to break down oils

- Use clarifier to help filtration

- Increase regular chlorine levels

Equipment Problems

Pump Issues

Pump Won’t Start

Diagnostic steps:

- Check electrical connections – GFCI, breakers, timer

- Inspect for obvious damage – Cracked housing, loose wires

- Listen for sounds – Humming, clicking, or silence

Common causes and solutions:

No power reaching pump:

- Check GFCI outlet and reset if needed

- Verify timer settings and operation

- Check circuit breaker for tripped position

Pump has power but won’t run:

- Capacitor failure (humming sound) – Replace capacitor

- Seized impeller – Remove debris from impeller housing

- Motor failure – Professional diagnosis needed

Pump starts but shuts off immediately:

- Overheating protection activated

- Check for adequate ventilation around motor

- Inspect for blocked impeller or low water flow

Low Water Pressure/Flow

Symptoms:

- Weak water flow from return jets

- Low pressure reading on filter gauge

- Poor skimming action

Systematic diagnosis:

- Check skimmer and pump baskets – Empty if full

- Inspect filter condition – Clean or backwash if dirty

- Look for suction leaks – Air bubbles in pump basket

- Verify valve positions – All suction valves open

Tennessee-specific causes:

- Heavy pollen clogs baskets quickly

- Storm debris overwhelms filtration

- High bather loads during extended season

Pump Losing Prime

Symptoms:

- Pump basket not staying full of water

- Air bubbles visible in pump basket

- Intermittent pressure readings

Common causes:

- Cracked pump lid or damaged O-ring

- Loose pipe connections on suction side

- Low water level in pool

- Blocked skimmer or suction line

Solution steps:

- Check water level – Should be halfway up skimmer opening

- Inspect pump lid seal – Clean and lubricate O-ring

- Tighten all suction-side connections

- Look for cracks in plumbing – Especially around unions

- Prime pump manually and monitor for air leaks

Filter Problems

Sand Filter Issues

Poor filtration despite backwashing:

- Sand media needs replacement (every 3-5 years)

- Sand has channeled, creating bypass paths

- Multiport valve problems

Frequent backwashing needed:

- High organic load overwhelming filter

- Sand media breakdown creating fine particles

- Inadequate pre-filtration (baskets not cleaned)

Solution approach:

- Replace sand media if over 3 years old

- Increase skimmer basket maintenance

- Add clarifier to improve filtration efficiency

- Consider DE powder addition for enhanced filtration

Cartridge Filter Issues

Short cartridge life:

- High debris load from Tennessee storms

- Inadequate basket maintenance

- Pool chemistry imbalance causing rapid fouling

Cartridges won’t clean properly:

- Oil and sunscreen buildup requires degreasing

- Mineral deposits need acid cleaning

- Cartridges worn beyond cleaning ability

Maintenance schedule:

- Weekly: Rotate cartridges, clean dirty set

- Monthly: Deep clean with degreaser and acid

- Annually: Replace cartridge set completely

DE Filter Issues

Poor water quality despite adequate DE:

- Filter grids damaged or worn

- DE powder quality issues

- Inadequate DE amount added

Frequent DE loss:

- Cracked grids allowing DE bypass

- Multiport valve problems

- Improper backwashing technique

Heater Problems

Heater Won’t Ignite

Gas heater troubleshooting:

- Check gas supply – Valve open, pilot light lit

- Verify electrical power – 120V to control board

- Test water flow – Flow switch operation

- Inspect venting – Clear of obstructions

Heat pump troubleshooting:

- Check electrical supply – 220V power available

- Verify refrigerant levels – Professional diagnosis

- Clean coils – Remove debris and buildup

- Test defrost cycle – May appear to malfunction

Heater Runs But No Heat

Possible causes:

- Insufficient water flow through heat exchanger

- Scale buildup reducing heat transfer

- Thermostat calibration problems

- Heat exchanger damage or corrosion

Tennessee factors:

- Hard water accelerates scale formation

- High heat demand stresses equipment

- Extended season increases wear

Diagnostic steps:

- Check water flow rate – Should meet manufacturer specs

- Inspect heat exchanger for scale or corrosion

- Test thermostat accuracy with separate thermometer

- Professional inspection for internal damage

Automatic Cleaner Problems

Suction-Side Cleaner Issues

Cleaner moves slowly or not at all:

- Insufficient suction due to clogged baskets or filter

- Suction leak reducing cleaner performance

- Worn cleaner parts need replacement

Cleaner gets stuck repeatedly:

- Pool hydraulics create low-flow areas

- Cleaner needs adjustment or different model

- Obstacles in pool interfering with movement

Pressure-Side Cleaner Issues

Cleaner not moving:

- Booster pump problems

- Clogged pressure line

- Worn cleaner drive mechanism

Poor cleaning performance:

- Incorrect water flow adjustment

- Worn brushes or cleaning components

- Pool design incompatible with cleaner type

Chemical Balance Problems

pH Won’t Stay Balanced

pH Keeps Rising

Common in Tennessee due to:

- Salt water chlorine generators

- Heavy aeration from waterfalls or fountains

- High total alkalinity levels

Solutions:

- Lower total alkalinity to 80-100 ppm range

- Add pH decreaser regularly (stock up when on sale)

- Reduce aeration during peak pH rise periods

- Consider acid feeder for consistent control

pH Keeps Dropping

Causes:

- Acidic rainfall (common in Tennessee)

- Over-chlorination with trichlor tablets

- Low total alkalinity providing no buffer

Solutions:

- Increase total alkalinity to 120-150 ppm

- Switch to calcium hypochlorite instead of trichlor

- Cover pool during heavy rains if possible

- Test more frequently during weather changes

Chlorine Problems

Chlorine Disappears Quickly

High chlorine demand causes:

- Algae growth consuming chlorine

- High bather load creating contaminants

- Insufficient stabilizer allowing UV destruction

- Organic matter requiring oxidation

Tennessee factors:

- Intense UV destroys unstabilized chlorine

- High temperatures accelerate chlorine consumption

- Extended swimming season increases demand

Systematic approach:

- Test stabilizer level – Should be 30-50 ppm

- Shock heavily to eliminate chlorine-consuming contaminants

- Increase regular chlorine dosing

- Add algaecide as preventive measure

- Test for phosphates if problems persist

High Chlorine But Algae Growth

Chlorine lock situation:

- Stabilizer levels too high (over 80 ppm)

- pH too high reducing chlorine effectiveness

- Chloramines present instead of free chlorine

Solutions:

- Test actual free chlorine vs total chlorine

- Lower pH to 7.2 for maximum effectiveness

- Shock to break chloramines if present

- Partial water replacement if stabilizer over 80 ppm

Total Alkalinity Issues

Alkalinity too low (under 80 ppm):

- pH bounces wildly with any addition

- Water becomes corrosive to equipment

- Swimmer discomfort from unstable chemistry

Alkalinity too high (over 150 ppm):

- pH difficult to adjust

- Scale formation accelerates

- Cloudy water despite proper filtration

Balancing approach:

- Adjust alkalinity first before correcting pH

- Make small changes – 10-20 ppm adjustments

- Allow circulation time before retesting

- Maintain 100-120 ppm for stability

Seasonal Problem Patterns

Spring Problems (March-May)

Common issues:

- Green water from winter algae growth

- Equipment failures after winter shutdown

- Chemical imbalances from weather changes

- Heavy pollen affecting filtration

Prevention strategies:

- Proper winter maintenance

- Gradual equipment startup

- Frequent chemical testing during transition

- Enhanced filtration during pollen season

Summer Problems (June-August)

Peak season challenges:

- High bather load overwhelming sanitation

- Equipment overwork from extended runtime

- Rapid chemical consumption from heat and UV

- Storm damage and dilution

Management approaches:

- Increase chemical testing frequency

- Higher sanitizer levels during peak use

- Enhanced equipment maintenance

- Storm preparation and recovery plans

Fall Problems (September-November)

Transition season issues:

- Leaf debris overwhelming skimmers and filters

- Temperature swings affecting chemistry

- Reduced attention as season appears to end

- Equipment preparation for winter

Tennessee fall strategy:

- Continue full maintenance longer than northern climates

- Enhanced debris removal systems

- Gradual chemical reduction, not elimination

- Equipment winterization timing based on weather

When to Call a Professional

DIY vs Professional Diagnosis

Handle yourself:

- Basic water chemistry imbalances

- Simple equipment maintenance

- Routine cleaning and debris removal

- Minor equipment adjustments

Call a professional:

- Electrical problems with equipment

- Gas appliance issues

- Structural problems with pool surfaces

- Repeated failures of the same equipment

- Chemical problems that don’t respond to treatment

Tennessee Professional Resources

What to look for:

- Local presence and reputation

- Experience with Tennessee climate challenges

- Proper licensing and insurance

- Willingness to explain problems and solutions

- Fair pricing with written estimates

Questions to ask:

- How long have you served Tennessee pools?

- What’s your experience with this specific problem?

- Can you explain why this happened?

- What can I do to prevent recurrence?

- Do you guarantee your work?

Prevention: The Best Troubleshooting

Weekly Prevention Checklist

Chemical management:

- Test pH, chlorine, and alkalinity

- Adjust chemicals before problems develop

- Maintain proper sanitizer levels consistently

Equipment monitoring:

- Check pump and filter operation

- Empty skimmer and pump baskets

- Inspect automatic cleaner performance

- Listen for unusual equipment noises

Physical maintenance:

- Brush walls and steps

- Remove debris before it sinks

- Check water level and maintain proper height

- Visual inspection for developing problems

Tennessee Climate Adaptations

Heat management:

- Increase chemical testing during heat waves

- Run equipment longer during extreme temperatures

- Monitor equipment for overheating

- Maintain adequate water levels

Storm preparation:

- Secure loose equipment before storms

- Test chemistry after heavy rains

- Remove storm debris promptly

- Check equipment operation after power outages

Seasonal transitions:

- Adjust maintenance routines gradually

- Don’t shut down too early in fall

- Start up equipment properly in spring

- Maintain chemical balance year-round

Emergency Action Plans

Green Water Emergency

Immediate actions:

- Stop swimming until problem resolved

- Test water chemistry immediately

- Begin shock treatment protocol

- Increase filtration to maximum

- Add copper algaecide for rapid response

Equipment Failure Emergency

Safety first:

- Turn off electrical power to failed equipment

- Stop using pool if safety systems affected

- Document problem with photos if possible

- Call professional for electrical or gas issues

- Implement backup systems if available

Chemical Accident Emergency

Immediate response:

- Remove people from pool area

- Ventilate area if chemicals were mixed improperly

- Flush with water for skin or eye contact

- Call poison control for serious exposure

- Don’t add more chemicals until situation stabilized

Conclusion

Pool troubleshooting is part science, part experience, and part detective work. The key to success is systematic diagnosis that identifies root causes rather than just treating symptoms. Tennessee’s challenging climate means our pools face unique stresses that require adapted solutions and preventive strategies.

Remember that most pool problems are preventable through proper maintenance, regular testing, and prompt attention to developing issues. The cost of prevention is always less than the cost of major repairs or replacement.

When problems do arise, don’t panic and don’t throw random chemicals at symptoms. Follow systematic diagnostic procedures, address root causes, and don’t hesitate to seek professional help when problems are beyond your comfort level.

Your pool is a significant investment that can provide years of enjoyment when properly maintained. Understanding how to troubleshoot and solve problems is essential to protecting that investment and ensuring safe, comfortable swimming for your family.

🎯 Troubleshooting Success: “The best pool owners aren’t those who never have problems – they’re those who identify problems early and fix them correctly the first time.”

Dealing with a pool problem not covered in this guide? Describe your specific symptoms and recent pool history in the comments below. With details about your situation, water test results, and recent changes, we can help you develop a targeted solution plan for your Tennessee pool.